Component optimization

Most metal parts that customers request to be 3D printed do not conform to the shape requirements of additive manufacturing. The design of the parts matches their function, but the shape is not suitable for 3D printing. These aspects lead to the production of support elements that slow down the production process, make production more expensive and are in in most cases difficult to remove.

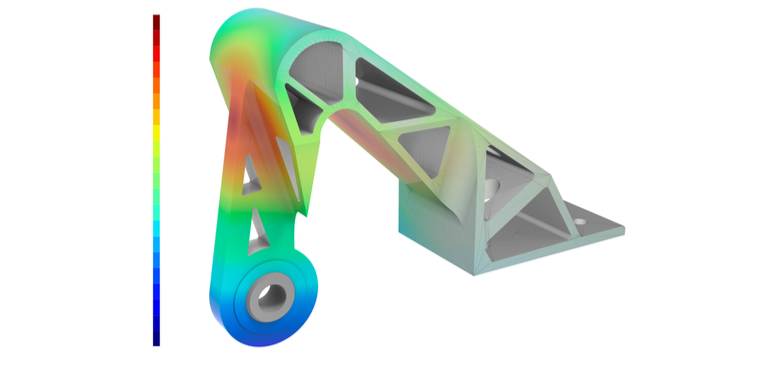

We perform topology optimization of the model, which means finding the best geometric shape of the component at known boundary conditions. By using this technique, we can design the shape of the component with significant volume and weight savings, while maintaining the same strength or improving it.

- Weight and price savings

- Production acceleration